Overview - Delivering Industry 4.0 Together

The Industrial Edge has unique distributed computing, protocol, data, ML, security and integration challenges not found in retail, consumer or other edge markets.

Fledge is the Linux Foundation's Industrial Internet of Things (IIoT) edge platform and community architected for and built by industrial users, machine builders, smart industrial sensor suppliers, industrial software suppliers, system integrators and cloud operators. The Fledge project was seeded by Dianomic, Google, AVEVA/OSIsoft, Teledyne/FLIR and JEA (8th largest utility in the U.S.). Our community is growing fast with over 60 contributors. Fledge is also adopted by LF Energy (Fledge Power Project), OSDU and is being evaluated by CESMII.

-------------------------------------------------------------------------------------------------------------------------

Some quick links:

For Machine Builders, System Integrators, Smart Sensor Suppliers, Industrial Software Suppliers and Contributors

For Users and No Code Application Developers

-----------------------------------------------------------------------------------------------------------------------

Back To The Overview

Fledge has been deployed in industrial operations since 2019! Some of our public use cases include:

- JEA - Energy substation monitoring and automation

- RTE - Energy RTU server gateway (IEC104, IEC61850, TASE 2, OpenADR)

- General Atomics - Military drone manufacturing

- Neuman Aluminum - Aluminum part manufacturing

- Honda Racing - Digital Twin machine optimizations

- Opus One/UC Davis - Wine production and safety

Some of our private use cases include:

- Large gas pipeline operator - Remote monitoring stations where SCADA doesn't reach

- Pharmaceutical company - Redundant PLC connections and data transformations to historians with HA for compliance

- Major chemical company - Multi-protocol gateway in the cloud connecting 200,000 LoRaWan sensors and API gateway connecting cloud services to historians

- Midwest electric generator - Replace route based monitoring in gas turbine plants

- Large food processor - Centrifuge optimization using ML with vibration and PLC data

- Small engine manufacturer - Monitor robot and CNC process for real-time part quality inspection with track and trace integrated with MS Azure and historian

- Amusement park solar farm - solar tracker monitoring

Strategic Collaborations

- AVEVA - Integrates data with PI, AVEVA Data Hub, pulls data from PI

- ACDP - MS Azure Integration

- Beckhoff - Collects data from PLCs

- Cisco - Operates in Cisco containers

- FLIR - Connects, collects and integrates FLIR cameras, Spinnaker for Computer Vision applications, REST for data feeds

- Google - Integrates Google's IoT Core, GC Pub/Sub, TensorFlow, Tensorflow Lite, AutoML, ML Edge

- HarperDB - Integrates data with DB

- Nexcom -J1939 and J1708 integrations, Coral integration

- Nokia - Integrates NDAC private LTE and 5G

- ThinkIQ - Integrates

- Wago - Collects data from PLCs, operates in container

- In Progress

- AWS Sitewise Integration

We invite you to use Fledge and contribute to the Fledge Project. And, we look forward to delivering the Industrial 4.0 vision together.

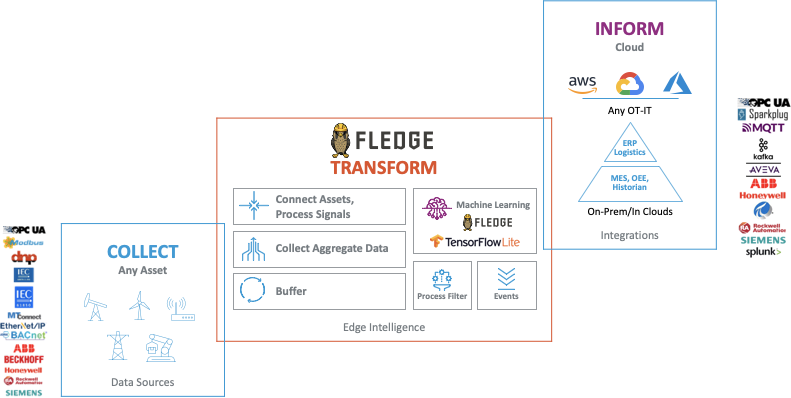

Collect, Transform,Integrate - Industrial IoT Fundamentals

Fledge connects to all OT data sources (PLCs, DCS, CNC, robots, sensors, etc) supporting the many legacy, current and emerging protocols, networks and methods found in industrial use. The data types from these machines goes beyond time-series data including image, vibration, radio metric and more.

Second, Fledge collects and aggregates this data on the edge.

Third, Fledge transforms, processes, filters, stores, analyzes, alerts and notifies on the edge. Applications may be as simple as converting celsius to Fahrenheit or multi-protocol gateway transformations that map data from different schemas/protocols or as complex as ML/AL and computer vision detecting anomalies or optimizing operations from the edge.

Fourth, Fledge has bi-directional write capability for set-point control. Using Linux, this control function is not intended for RTOS applications. However, it is suitable for writing PLC instructions or sub-second control functions.

Last, Fledge Integrates the data to any and multiple destinations simultaneously creating a smart secure and scalable OT data fabric from sensors and machines to industrial systems and clouds.

Industry 4.0 Requires a 4.0 Edge

Fledge - The Open Source Industry 4.0 Edge Governed by the Linux Foundation

Features | Benefits |

Universal Data Acquisition (Any sensor, machine, system) | Connect Everything |

Universal Data Integration (ISA95, Any Cloud) | No Data Silos – IT/OT Convergence |

Setpoint Control (Bi-directional write, example MES to PLC) | Automation |

Extract Once – Use Many - Source Truth | No Data Silos, Trust Data, Cost, Manage |

Edge Analytics – Data Transformations & ML | Solves Latency, Data Volume |

Event Detection and Notification | Alert Organization (faults, optimizations, actions, safety) |

No/Low/Source Code Application Dev | Enables All Organizations (Ops, Engineering, IT, DevOps, Maint…) |

Edge Buffer/HA | Compliance, Reliability |

Compliment-Integrate w/ Control System | Supports All Organizations |

Multiple Data Types (TS, image, Radiometric, Vibration) | No Data Silos, Consistent APIs, Scale, Management |

Scale Up-Out | Security, Reliability, Usability (Delight ITops, Secops, Netops, Devops) |

No Vendor Lock – Apache 2 – Open Governance | Support, Control, Flexibility, Cost |

Intel, ARM, nVidia, Google Coral – Any Linux | Open - No Vendor Lock |

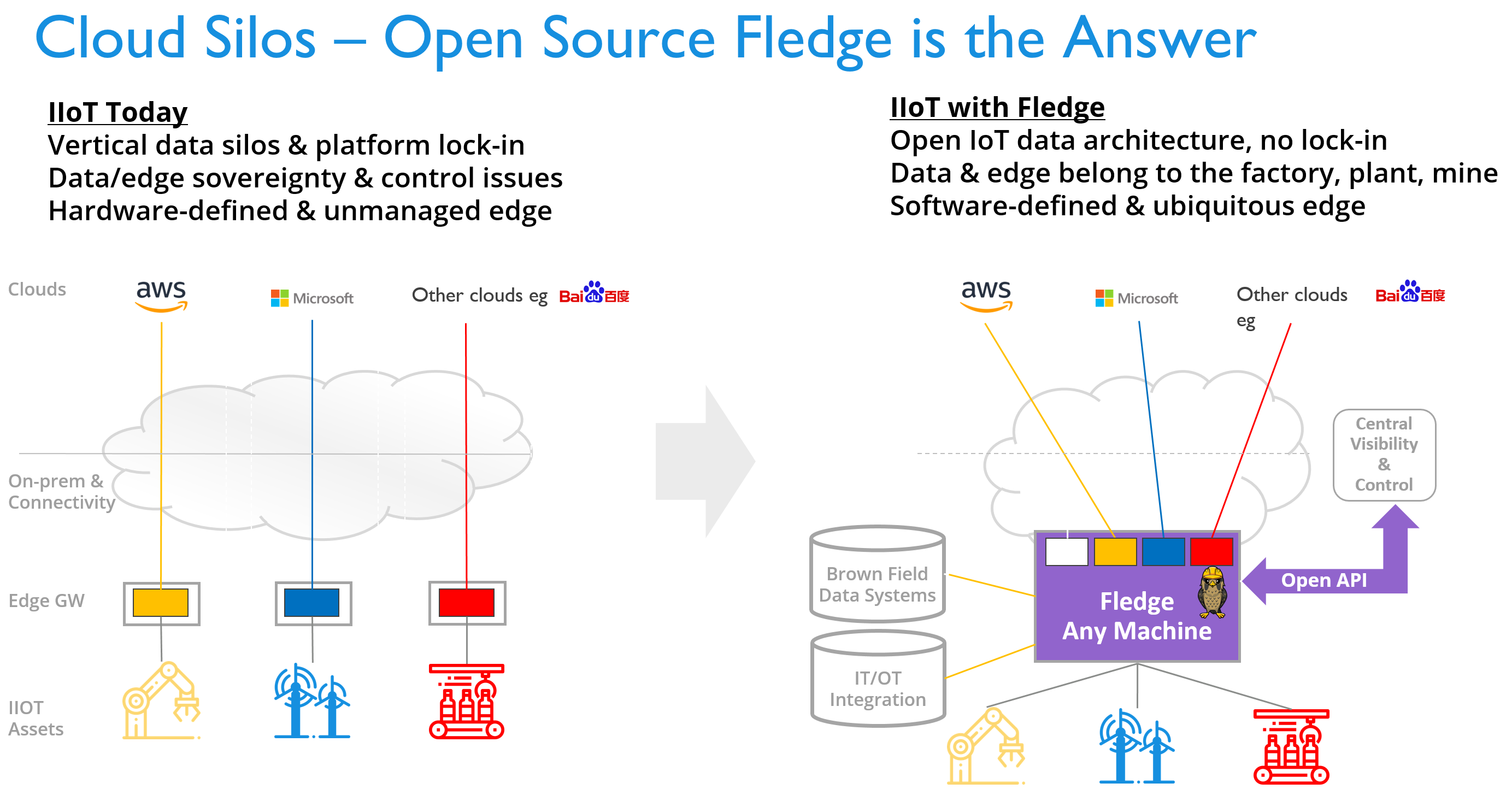

Fledge developers and operators no longer face complexity and fragmentation issues when building their IIoT applications as they gather and process more machine and sensor data to automate and transform business. Fledge’s modern pluggable architecture eliminates the data silos often found in plants, factories and mines. By using a consistent set of RESTful APIs to develop, manage and secure IIoT applications, Fledge creates a unified, scalable, manageable and secure converged OT-IT edge solution.

Join Us as our community delivers the benefits of a shared open source stack to OT users and suppliers sharing the Industry 4.0 Vision.

Welcome to the Fledge Wiki

Overview

Fledge developers build smarter, better, more cost effective industrial manufacturing solutions to accelerate Industrial 4.0 adoption.

Fledge is an open source framework and community for the Industrial Edge. Architected for rapid integration of any IIoT device, sensor or machine all using a common set of application, management and security REST APIs with existing industrial "brown field" systems and clouds. Fledge edge services include: Collect Data from any/all sensors, aggregate/combine/organize data. edge based alerting/anomaly detection/machine learning (TensorflowLIte, OpenVino), transform/filter data in flight, buffer data, analyze/visualize edge data, and deliver data to multiple local/cloud destinations.

Fledge developers and operators no longer face complexity and fragmentation issues when building their IIoT applications as they gather and process more sensor data to automate and transform business. Fledge’s modern pluggable architecture eliminates the data silos often found in plants, factories and mines. By using a consistent set of RESTful APIs to develop, manage and secure IIoT applications, Fledge creates a unified solution.

For Industrial Equipment Vendors - Build Your Next Generation Machines smarter and more autonomous

- That learn

- Maintain themselves

- Integrate with your new cloud services

- Integrate with your customer’s existing and emerging data systems

- Enable new business models/higher margins

For Industrial Operators - Get All Your Data Where It Needs to Be

- Condition and predictive maintenance on all machines

- Cost effective vs using DCS or SCADA points

- Put all data in plant wide context

- Scale out and up manageable IIoT

- Eliminate OT data complexity and fragmentation

For Industrial System Integrators - A Framework for All Your IIoT Business

- Accelerate deployments

- More/tighter integrations

- Own and re-use your value-add code

- Develop AD/ML/AI expertise

- Increase value delivered/hour

The growing Fledge community is committed to:

- Foster cross-industry collaboration across IoT, Telecom, Enterprise and Cloud ecosystems

- Enable organizations to accelerate adoption and the pace of innovation for edge computing

- Facilitate harmonization across LF Edge projects

Architecture

Cross Project Collaboration

Fledge works closely with Project EVE, which provides system and orchestration services and a container runtime for Fledge applications and services. Together industrial operators can build, manage, secure and support all their non-SCADA, non-DCS connected machines, IIoT and sensors as they scale.

Fledge is also integrated with Akraino Edge Stack, as both projects support the roll out 5G and private LTE networks.

It also complements EdgeX Foundry on the industrial side. EdgeX has extensive control features, focused more where data management and integrated control are required and Fledge specifically works when data from brown field systems is not connected to the primary control systems (often serviced by RBM) and environmental/situational/safety sensors.

Contributed by Dianomic and formerly known as “Fog Lamp,” Fledge developers build smarter, better, more cost-effective industrial manufacturing solutions to accelerate Industrial 4.0 adoption. Fledge joins LF Edge as a Stage 1 project.

Get started with Fledge

Join Mail Lists: https://lists.lfedge.org/g/main/subgroups

Discuss in Slack: https://slack.lfedge.org

(#fledge / #fledge-help / #fledge-tsc)

Latest Fledge NewsRecent space activity

| Recently Updated | ||||||||

|---|---|---|---|---|---|---|---|---|

|