Overview

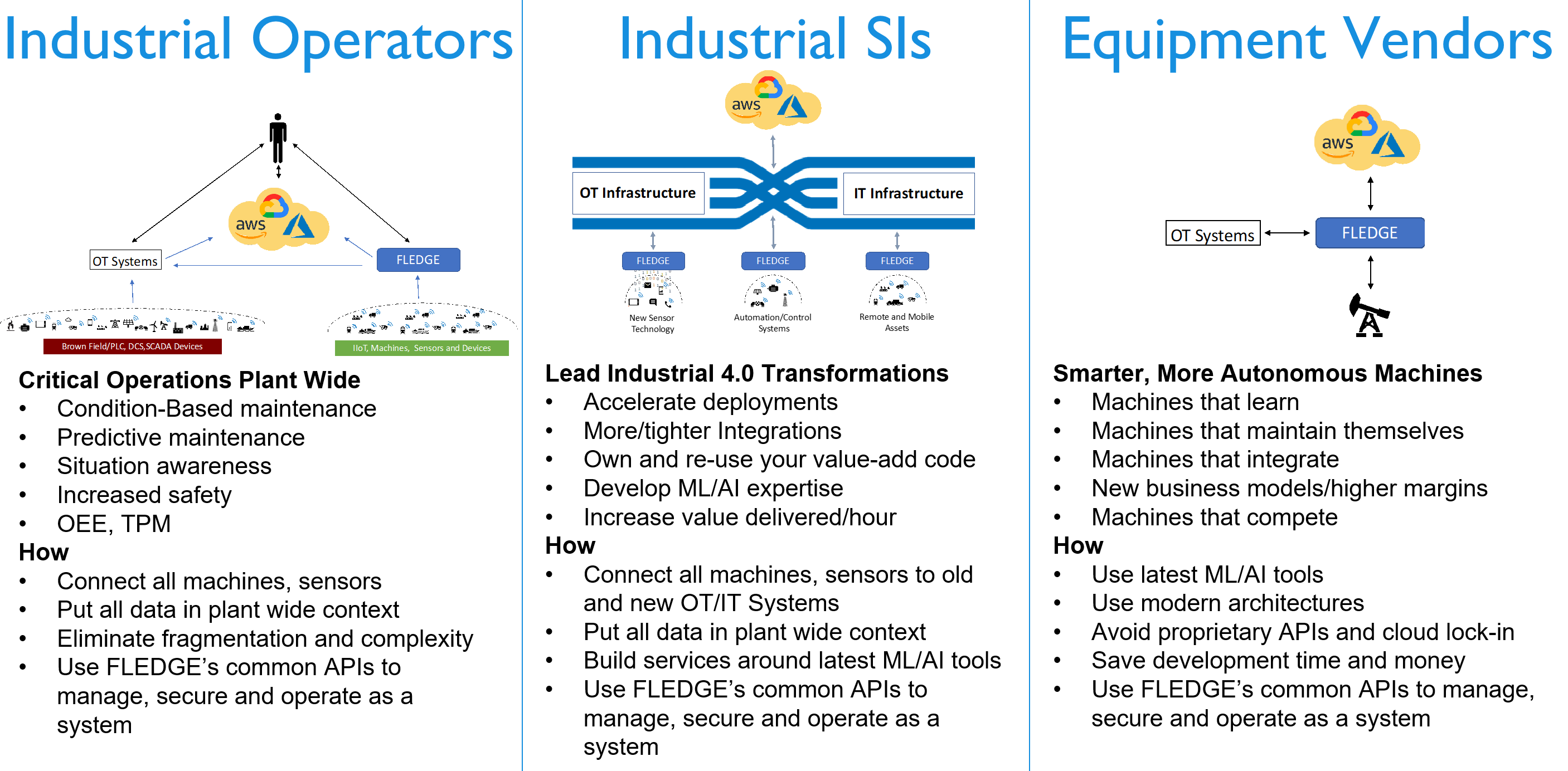

Edge computing is a challenging distributed computing problem.The fragmentation and distribution of industrial data, networking, processing, security and storage makes managing it complicated. Simplifying industrial IoT application and system development with a ubiquitous open source stack, standards, and community is our mission.

Fledge is an open source framework and community for the Industrial Edge. Architected for rapid integration of any IIoT device, sensor or machine all using a common set of application, management and security REST APIs with existing industrial "brown field" systems and clouds.

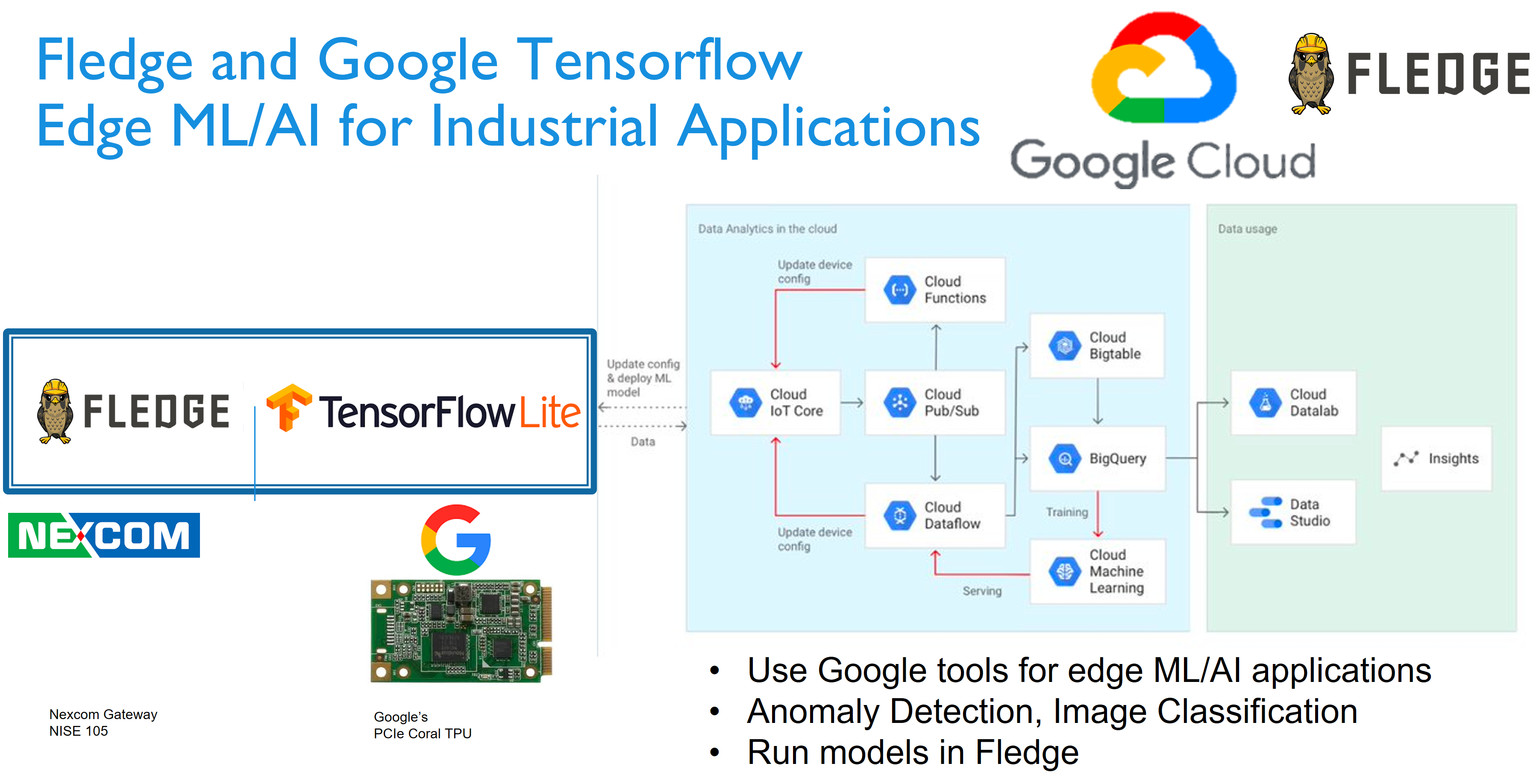

Fledge edge services include: Collect Data from any/all sensors, aggregate/combine/organize data. edge based alerting/anomaly detection/machine learning (TensorflowLIte, OpenVino), transform/filter data in flight, buffer data, analyze/visualize edge data, and deliver data to multiple local/cloud destinations.

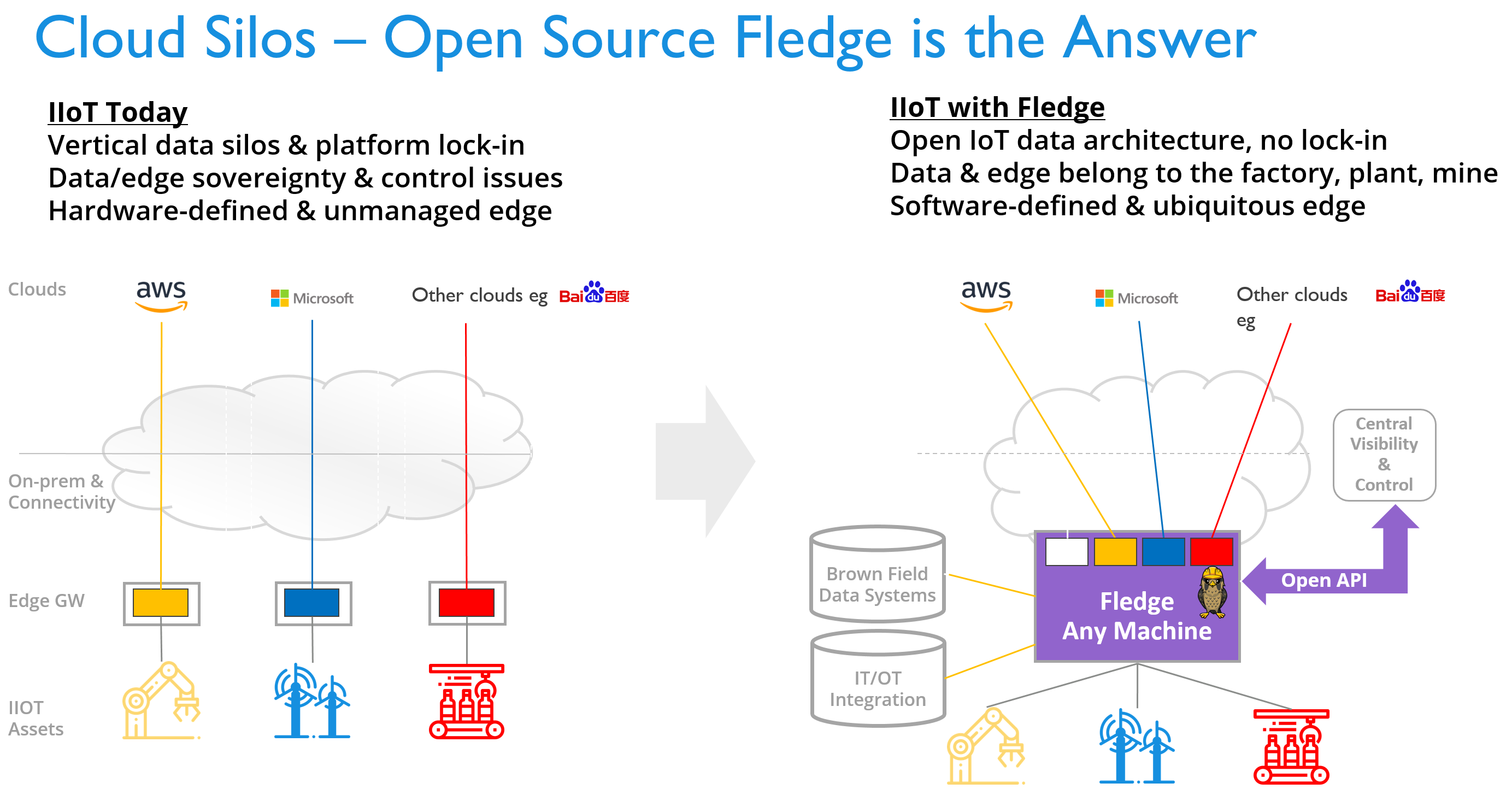

Fledge developers and operators no longer face complexity and fragmentation issues when building their IIoT applications as they gather and process more sensor data to automate and transform business. Fledge’s modern pluggable architecture eliminates the data silos often found in plants, factories and mines. By using a consistent set of RESTful APIs to develop, manage and secure IIoT applications, Fledge creates a unified solution.

Use Cases

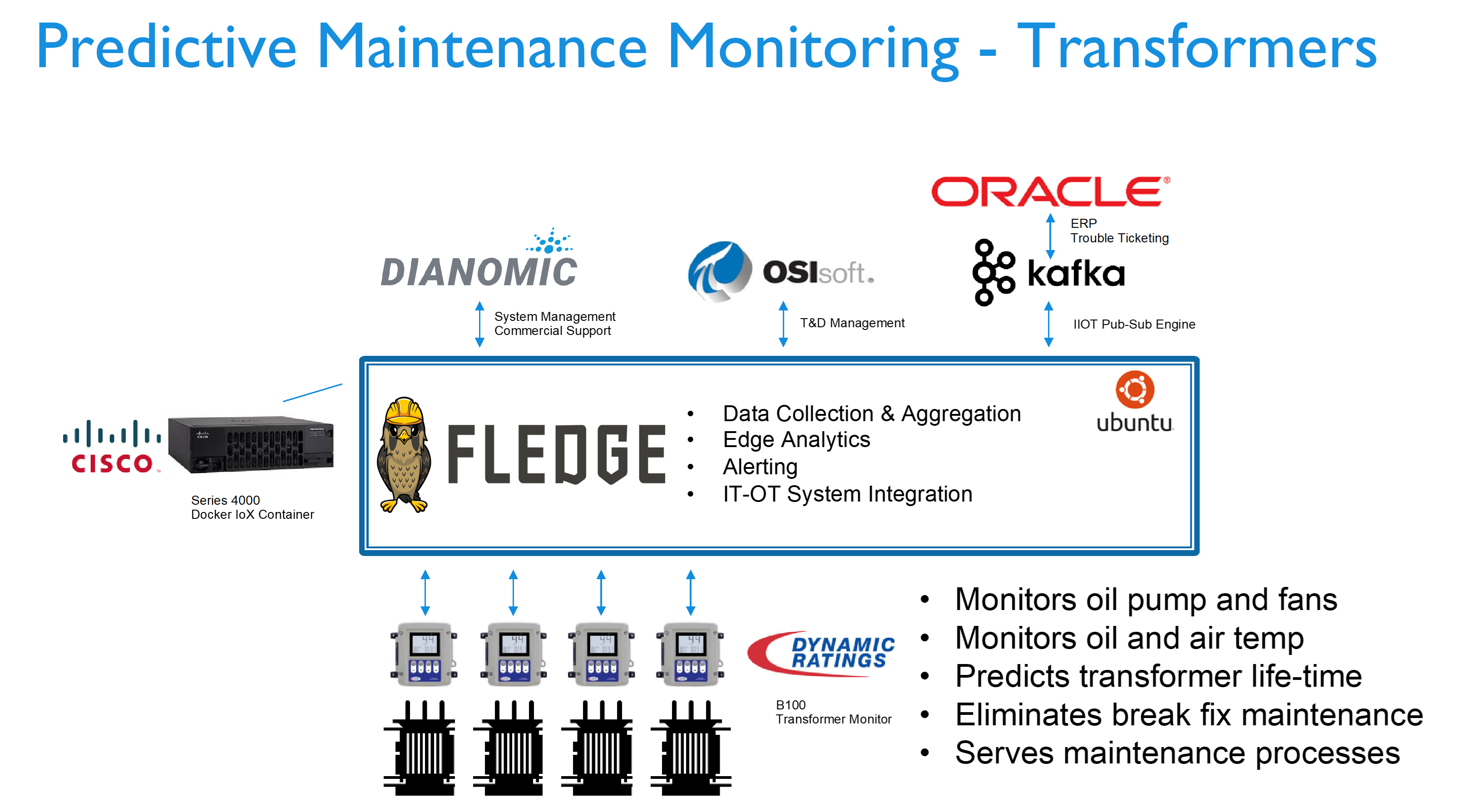

JEA spends millions on transformer maintenance due to unexpected failures. JEA uses Fledge to monitor oil pumps, oil temperature, fans, ambient air temperature and hydrogen gas levels on substation transformers. This condition-based IIoT system avoids using expensive SCADA hardware by leveraging Cisco switches. Fledge then integrates the sensor data into JEA’s historians and maintenance systems.

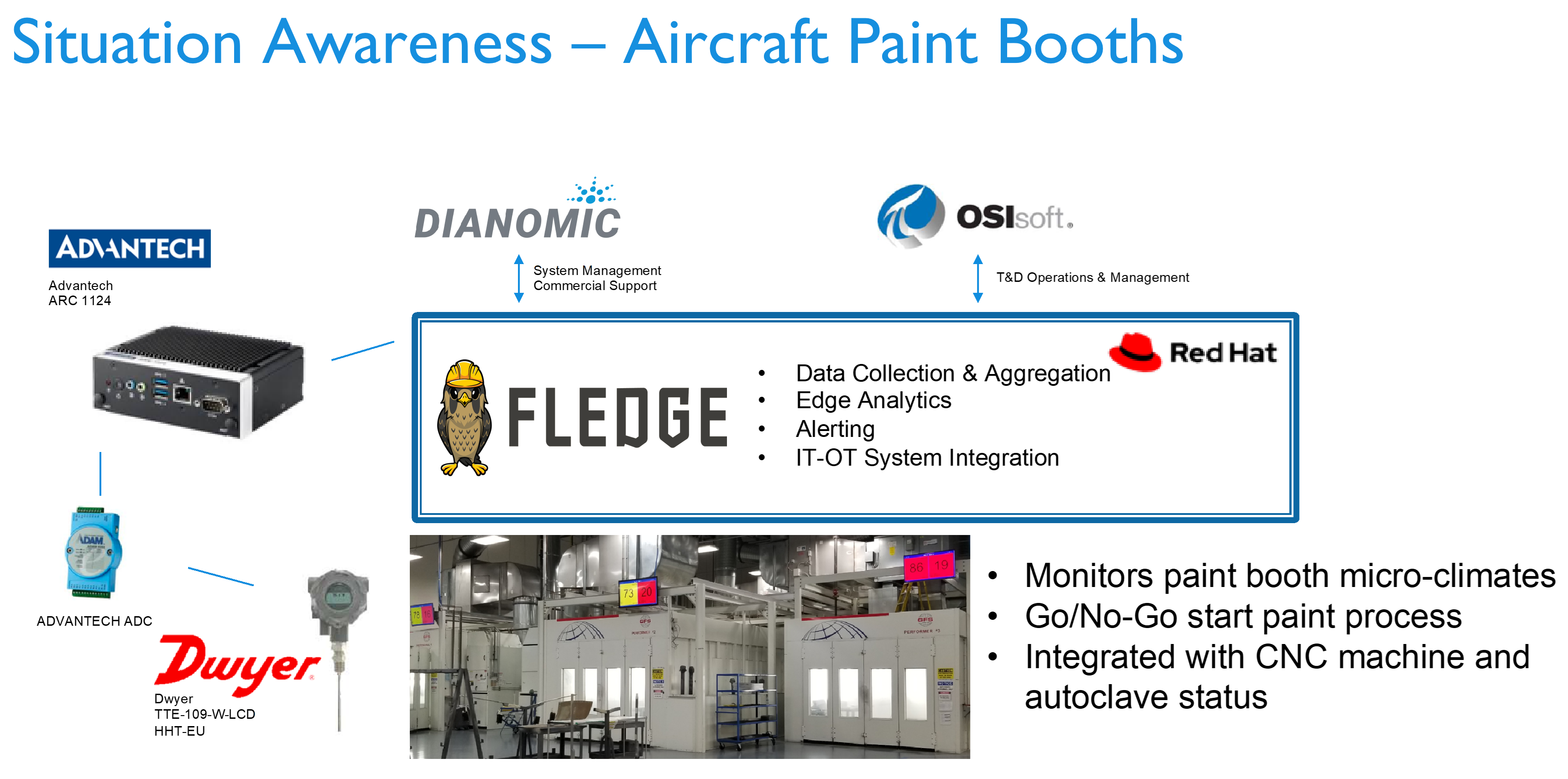

Military drone composite materials require specific temperature and humidity conditions during painting and curing. Entire aircraft may need to be reworked if conditions are improper. Using Fledge, Dwyer TTE Explosion-Proof sensors were deployed in 6 locations/paint booth. Fledge readings and alerts informed operational control systems, historians as well as large monitors authorizing processes on each assembly line.

Cross-LF Edge Collaboration

Fledge works closely with Project EVE, which provides system and orchestration services and a container runtime for Fledge applications and services. Together industrial operators can build, manage, secure and support all their non-SCADA, non-DCS connected machines, IIoT and sensors as they scale.

Fledge is also integrated with Akraino Edge Stack, as both projects support the roll out 5G and private LTE networks.

It also complements EdgeX Foundry on the industrial side. EdgeX has extensive control features, focused more where data management and integrated control are required and Fledge specifically works when data from brown field systems is not connected to the primary control systems (often serviced by RBM) and environmental/situational/safety sensors.

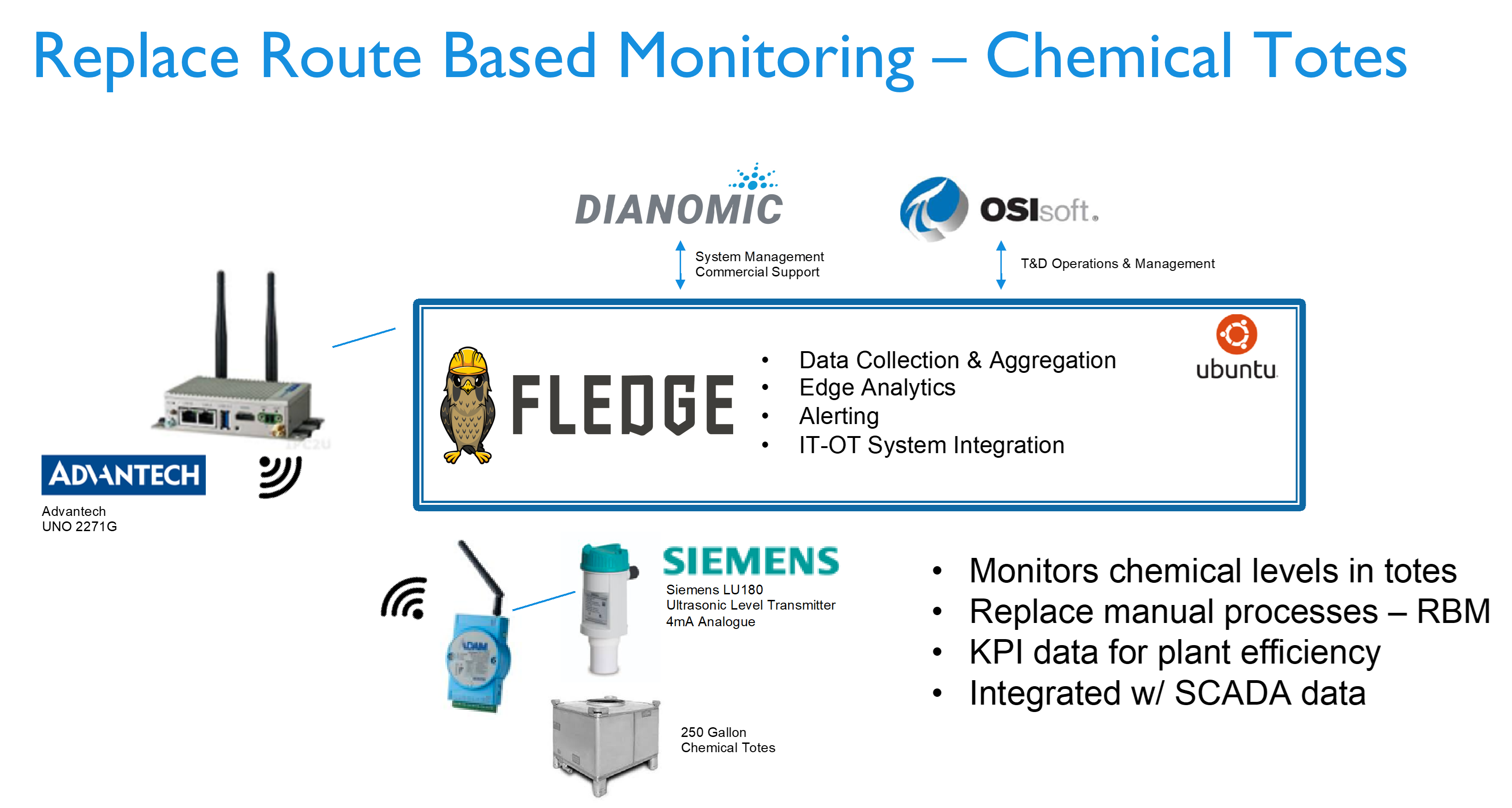

Contributed by Dianomic and formerly known as “Fog Lamp,” Fledge developers build smarter, better, more cost-effective industrial manufacturing solutions to accelerate Industrial 4.0 adoption.

Recent space activity