Status

- Presented during the Wednesday, June 3, 2020 TAC call: Meeting Recording (https://zoom.us/rec/share/6_JaCZry6zpOE8_D6UvGVelxQ7S_aaa81XUfqfIFyB1ZFEt8yNmKXkinACybVHnS)

- TAC Project Review underway

- Subgroup Review Meetings:

- June 9, 2020: Meeting Notes / Meeting Recording

- Subgroup Readout/s, TAC discussion: June 17 (Slides, Minutes, Recording) + July 1 (Slides, Minutes, Recording)

- Subgroup Review Meetings:

- TAC Vote Approved: July 9, 2020

- Governing Board Approved: July 19, 2020

Stage 2: Growth Stage (formerly 'Incubating')

Definition

The Growth Stage is for projects that are interested in reaching the Impact Stage, and have identified a growth plan for doing so. Growth Stage projects will receive mentorship from the TAC and are expected to actively develop their community of contributors, governance, project documentation, and other variables identified in the growth plan that factor in to broad success and adoption.

In order to support their active development, projects in the Growth stage have a higher level of access to marketing and other resources, which will be agreed upon and reviewed on a yearly basis by the TAC and then the Governing Board. A project's progress toward its growth plan goals will be reviewed on a yearly basis, and the TAC may ask the project to move to the At Large stage if progress on the plan drops off or stalls.

Examples

- Projects that are on their way or very likely to become Impact Stage Projects.

- Projects that have developed new growth targets or other community metrics for success.

- Projects that are looking to create a lifecycle plan (maintainership succession, contributor programs, version planning, etc.)

- Projects that need more active support from the Foundation in the form of marketing or TAC mentorship in order to reach their goals.

Expectations

Projects in the Growth Stage are generally expected to move out of the Growth stage within two years. Depending on their growth plans, projects may cycle through At Large, Growth, or Impact stage as needed.

Acceptance Criteria:

Development of a growth plan (to include both roadmap of projected feature sets as well as overall community growth/project maturity), to be done in conjunction with their project mentor(s) at the TAC.

The Fledge Project and Community growth plans are for the industrial market. The industrial market has a long history of using sensors, actuators, proprietary networks and proprietary systems to automate operations. The founding of the ISA was April 1945. A successful edge computing solution must integrate with the systems and processes and "edges" that already exist in factories, mines and plants in order to be accepted and "grow" the Fledge project and community. From that position, modern IIoT, Fog, cloud, ML services can evolve. Competing with SCADA, DCS, PLC and the rest of the "active" ISA95 stack is out of scope and would likely retard growth.

The Community’s History and Growth Plan

Zededa introduced Dianomic to the LF Edge before its inception and asked Dianomic to join as a founding board member. In that effort, Zededa and Dianomic worked with Mike Woster to encourage OSIsoft, to also join as founding members. The original idea was and remains to build a thriving open source industrial community. This is a challenge to the Linux Foundation in that industrial companies are not traditional open source users. The OT side of the Industrial market tends not to be software/compute experts, they are machine and process experts. So how have we grown the Fledge community and intend to exponentially grow it going forward?

To date the following companies are involved in coding, testing, writing documentation and contributing to the roadmap requirements.

Beckhoff - PLC Vendor | Nexcom - Industrial Gateways |

Dianomic - IIoT Software | Nokia - Wireless Communications |

Flir - IR/Gas Cameras | OSIsoft - Data Infrastructure |

General Atomics - Predator Drone | Rovisys - Industrial SI |

Google - Search-ML-Cloud-TPUs | Transpara - HMI for Process Manufacturers |

JEA - Energy/Water Company | Wago - PLC Vendor |

Motorsports.ai - Racing Digital Twins | Zededa - VMs for IoT |

All of these companies got involved due to use cases driving community participation. This organic community growth has accelerated during Covid not diminished. And, now with Fledge 1.8 complete, the new contributions will be made clearer with the LF Edges processes in place for all to track.

Second, there are a few anchor tenants in the industrial market and machine learning space that will grow the Fledge community with their involvement. OSIsoft has 22,000 servers deployed. Native connections to ISA95 systems grows the Fledge community. Google is arguably the premier ML supplier in the world. Google has contributed the Fledge North plugin to GC. Fledge will soon have 3 new major ML services contributed to Fledge from GC and Google will begin marketing those solutions with Fledge. In this effort, the Fledge community has sponsored multiple meetings between the LF Edge and Google to join.

Last, being focused on the industrial market means the community is focused too. Like most communications, speaking to the needs and requirements using a known/shared vocabulary is critical. Fledge with the LF Edge’s help communicates to these new types of users and prospective community members using “OT Speak” not computer jargon. Starting with our Fledge Mascot a fledgling peregrine falcon wearing a hard hat.

The Fledge Project’s Roadmap also drives community participation

- Adding 100s of new southbound plugins supporting the many protocols, data mappings and standards that encourage collecting machine and sensor data (legacy and emerging)

- Growing the community of interested parties to build these plugins

- Growing the community of Industrial System Integrators

- Support all major cloud IIoT onboarding APIs

- Google is our first major win. Google contributed the Fledge GC North plugin

- We would like to work with IBM on Watson and their focus on machines

- Support the major suppliers of ISA95 data managements services

- OSIsoft is our first major win (level 2-3) having 22,000 installs in process manufacturing

- Kafka to Oracle is our second (level 4) and was coded by an Industrial SI.

- Support the major ML toolkits being designed for machine and process automation - edge based.

- TensorflowLite - done

- OpenVino (Intel’s) - 2020 complete

- Watson?

- Support for unique industrial data workloads where edge processing is required like - digital signal processing.

- Improved UI. Industrials demand significant productization even for PoCs. This is a challenge for many open source initiatives. Fledge includes a UI and will have many enhancements that help visualize/understand context between sensor, machine, data streams/Fledge instance, component and Fledge hierarchies. (OpenFog Reference Architecture)

The Fledge roadmap also includes the integration and testing with systems and subsystems lower in the stack. This is an immediate opportunity for cross project cooperation.

- Life-cycle-management of HW and OS - EVE

- Fledge + EVE (FLIR camera demo) - Industrial Use Case

- Presented Working demo February 18 (reference meeting recording: 36:30 - 56:30)

- Fledge + EVE (FLIR camera demo) - Industrial Use Case

- Protocols/projects that enable IIoT "south of diodes" to be managed - Open Horizon

- Easy provisioning and life-cycle-management of emerging network edge technologies and services - Akraino

- Blueprint Proposal: https://wiki.akraino.org/pages/viewpage.action?pageId=20316568

- HW based key management to create “trusted” processes, devices, networks, communications and data services - Intel SDO

- Protocol bridge Fledge <> EdgeX – Discussed at joint Fledge TSC / EdgeX TSC call

Document that it is being used in POCs.

Fledge has been commercially deployed in Industrial Use Cases since early 2019 including the 3 public use cases/deployments below. The Fledge Training Lab has been attended by more than 150 Industrial companies. The Core Fledge Package has been downloaded by >1000 unique industrial users who have registered for code and updates. As Github Projects realize, counting source code downloads is misleading. Fledge has had 100,000s of downloads but counting unique users is not a Github feature.

Today Fledge has 3 public use cases.

General Atomics

A large defense and technologies company with more than 15,000 employees worldwide. They are a leading manufacturer of unmanned aerial vehicles (UAVs). These UAVs can be remotely piloted from anywhere in the world and are capable of very long duration, high altitude flights while carrying significant payloads. They are widely used by world militaries for intelligence, surveillance and offensive operations as well as by civilian organizations for border enforcement, firefighting and scientific applications.

The Need: UAVs are crafted from composite materials in an exacting process that demands high degrees of precision. If any step is executed under improper conditions, the entire aircraft may need to be reworked or even scrapped. The client wants to instrument every aspect of the manufacturing process to ensure that it is performed correctly and efficiently. By doing this, they expect to increase quality while reducing expenses from rework and scrappage. To completely monitor the production process, the client expects to deploy hundreds of sensors across multiple manufacturing stages. Data from these sensors must be available to personnel on the production floor, to supervisory personnel and for historic review.

The Solution: The key requirement for the project was a data management solution that could collect readings from hundreds of heterogeneous sensors and reliably transmit information to the multiple information systems that require it. To accomplish this, the client selected Fledge supported by Dianomic Systems. Fledge is an LF Edge Open Source project for industrial IoT that collects data from sensors, processes it at the edge, alerts and delivers it to data systems or the cloud. The client integrated Fledge with their existing operational systems to provide central monitoring and historical archiving. The initial stage of the project was to monitor the UAV painting process. UAVs are painted with multiple layers of primer and topcoat. These must be applied within strict ranges of temperature and humidity to ensure proper drying and curing. The client instrumented each paint booth with 4 temperature and humidity sensors one set in each corner. These sensors are attached to A/D converters and then to Fledge software running on Advantech Embedded IoT Gateways.

Fledge software converts the sensor readings to JSON format and reliably delivers the data to OSIsoft PI. In addition, Fledge connects with local displays at each paint booth to display temperature and humidity information on the factory floor. The display is green/red color coded to alert production personnel when environmental conditions are appropriate to begin the painting process.

The Results: Fledge-based monitoring has enabled the client to optimize the UAV painting process. Production now immediately begins when environmental conditions are met, eliminating the delays caused by manual measurement and communication. Supervisory personnel are alerted when conditions move outside specifications and can immediately rectify the situation. Further, manufacturing engineering now use historical data on temperature to better plan cycle times and to identify cost saving opportunities such as insulation and cooling devices. With the pilot project complete, the client is now moving towards their vision of complete visibility into the entire production process. Fledge’s open architecture will enable them to easily integrate the large numbers of varied sensors needed to ensure their operations are highly reliable and productive.

The next stage is to monitor autoclaves as they press and cure composite materials into UAV components. The client wants to review autoclave operations to ensure they have precisely executed the series of temperature/pressure/time stages necessary to eliminate bubbles and create structurally sound components. With the Fledge and PI infrastructures already in place, deploying monitoring for this process will be as simple as attaching additional pressure and temperature sensors to the Fledge gateways.

Link to Recording (Disclaimer: Foglamp instead of Fledge is used since it predates Fledge 1.8).

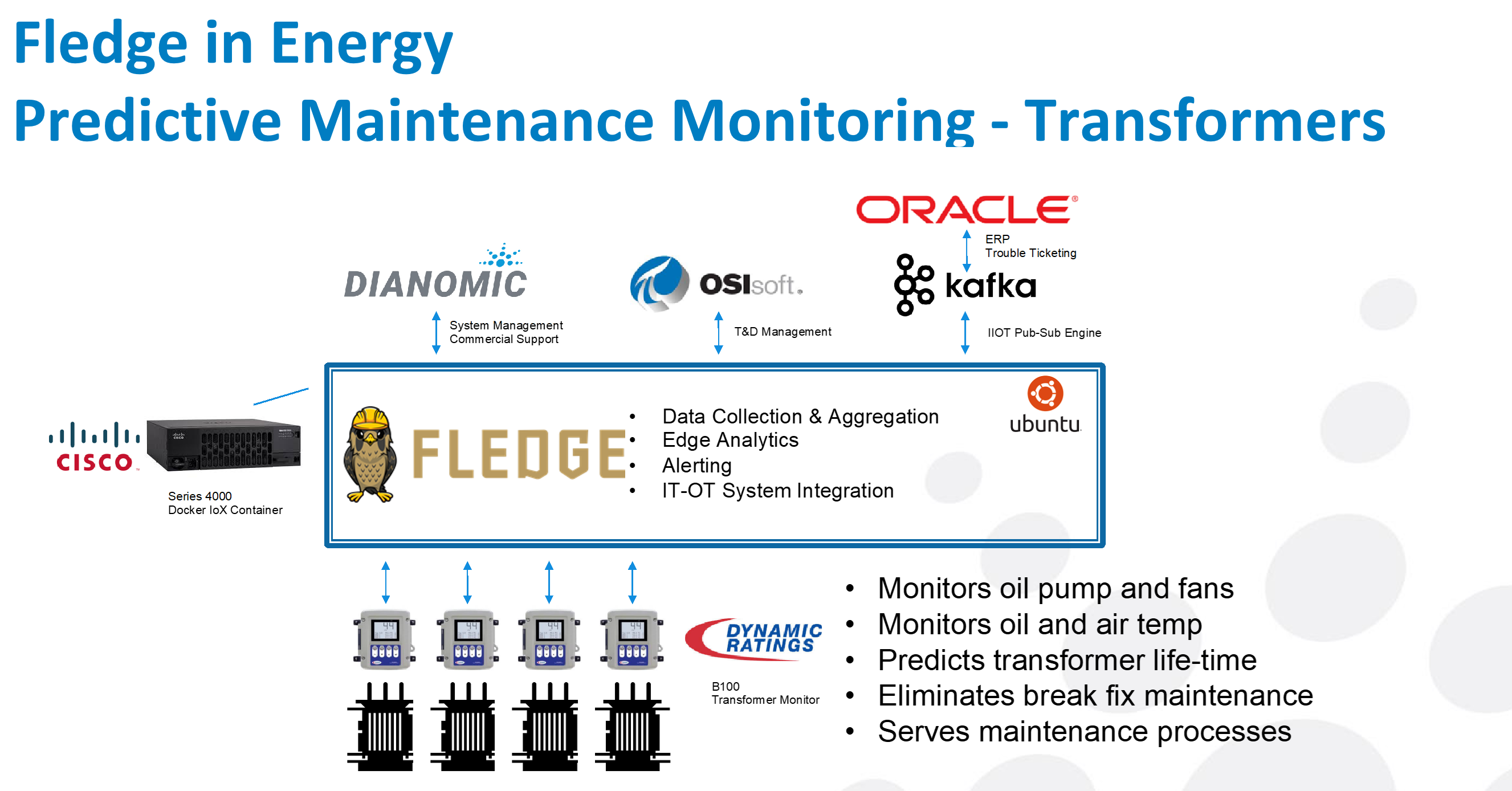

Jacksonville Energy Authority - A Leading Electrical Utility

This Fledge client is one of the largest community-owned electric utility companies in the United States, servicing nearly 500,000 customers in the United States. It operates five generating plants, about 750 circuit miles of transmission lines and nearly 7,000 miles of distribution lines. It also purchases energy from several solar sites located across its service territory, including one producer with more than 200,000 solar panels.

Reducing Reactive Repairs

The electrical utility spends millions of dollars on transformer maintenance each year. Much of this expense results from emergency responses to restore service due to failures in the field. They wanted to reduce these reactionary expenses and move to a proactive model where they could forecast systems requiring maintenance before failures actually occur. This will allow them to decrease outages while saving money by using their maintenance crews more effectively. Proactive maintenance requires a great deal of instrumentation and trend data on each transformer. This information needs to be available to multiple organizations across the enterprise for planning, analytics, monitoring and scheduling.

Fledge Enables Predictive Maintenance

The company decided that IIoT technology offered the best solution for this project. While they considered leveraging existing SCADA systems, they determined the cost to scale the hardware and licenses for these systems would be excessive. Further, security and NERC CIP regulatory concerns made it challenging to provide broad access to data residing in SCADA. Because of this, they decided to focus their SCADA systems on operation and controls and to use IIoT for condition-based monitoring and maintenance.

The company deployed Dynamic Ratings B100 Electronic Temperature Monitors at their substations. These measure power transformer top oil temperature and LTC temperatures and calculate winding temperatures. In addition, they made use of existing fan sensors to monitor ambient temperature.

To manage the edge data, the utility deployed Fledge, the Linux Foundation’s industrial IoT edge project supported by Dianomic Systems. Fledge is an open, industry-wide solution for monitoring the Internet of Things that collects data from sensors, processes it at the edge, alerts and delivers it to data systems or the cloud. Fledge’s open-source architecture provides a rapid, low-cost way to achieve complete visibility into information needed by businesses to operate more reliably and productively.

Fledge collects data from multiple B100s at the substation. It reliably delivers the data to OSIsoft PI for long-term trending, visualization, advanced analytics and event detection.

Because of Fledge’s open nature, the company was able to deploy it on their existing Cisco 4000 integrated services routers, saving the expense of additional ruggedized hardware.

Lower Costs and Fewer Outages

Fledge-based monitoring has enabled the utility to move to a much more proactive maintenance strategy. From OSIsoft PI, they can now detect the warning signs of transformer core, coil and LTC switch failures. Further, PI analytics can calculate cumulative thermal aging of the transformer to forecast life expectancy. Crews can be scheduled to perform maintenance before a failure occurs, resulting in much lower costs and less downtime.

The implementation has proven to be highly cost effective. Fledge’s flexibility enabled the company to leverage all its existing edge and back-end systems. Other than sensors, no new hardware was required for the deployment.

The utility plans to leverage Fledge’s flexibility to support additional IIoT use cases for field data management, integrating additional sensors and edge-based analytics to identify service requirements. Using Apache Kafka, Fledge will integrate with Oracle ERP to automatically generate maintenance work orders.

Link to Recording (Disclaimer: Foglamp instead of Fledge is used since it predates Fledge 1.8).

Google and Honda GT3 Racing - See LF Edge Blog Post

Demonstrate a substantial ongoing flow of commits and merged contributions.

Fledge 1.8 base was derived from FogLAMP 1.7 contributed code. FogLAMP 1.7 had ~50,000 commits. Here are the latest numbers, as reported by the Linux Foundation Edge.

| Cumulative Git Commits | Q4 2018 | Q1 | Q2 | Q3 | Q4 | Q1-2020 |

| EdgeX | 2834 | 3393 | 4060 | 4724 | 5250 | 6003 |

| Akraino | 195 | 439 | 1094 | 1563 | 1832 | 2076 |

| EVE | 3251 | 3843 | 4259 | 4608 | 5018 | 5603 |

| Home Edge | 69 | 209 | 217 | 223 | ||

| Glossary | 52 | 64 | 65 | 81 | 81 | 107 |

| Baetyl | 629 | 798 | 1123 | |||

| Fledge | 8317 | 8844 | 9102 | |||

| Artwork | 10 | 10 | 17 | |||

| State of the Edge | 396 | 529 | 631 | |||

| Total Git Commits | 6332 | 7739 | 9547 | 20537 | 22579 | 24885 |

Demonstrate that the current level of community participation is sufficient to meet the goals outlined in the growth plan.

Here are the latest numbers, as reported by the Linux Foundation Edge.

| Cumulative Unique Git Authors | Q4- 2018 | Q1-2019 | Q2 | Q3 | Q4 | Q1-2020 |

| EdgeX | 88 | 110 | 130 | 147 | 162 | 178 |

| Akraino | 16 | 43 | 78 | 97 | 104 | 105 |

| EVE | 34 | 39 | 46 | 50 | 57 | 62 |

| Home Edge | 8 | 10 | 11 | 11 | ||

| Glossary | 6 | 8 | 8 | 8 | 8 | 8 |

| Baetyl | 28 | 32 | 34 | |||

| Fledge | 45 | 45 | 46 | |||

| State of the Edge | 20 | 20 | 22 | |||

| Artwork | 3 | 3 | 5 | |||

| Total Git Authors | 144 | 200 | 270 | 408 | 442 | 471 |

The Fledge project is exclusively focused on the industrial market. From a SWOT (Strength-Weakness-Opportunity-Threat) perspective, this limits the audience of potential committers since consumer, home, retail, gaming etc developers are not a fit. An additional challenge in this market is the lack of open source culture with industrials, equipment manufacturers and industrial system integrators. The Fledge project has the goal of changing this culture. Of the current 46 Git Authors roughly 80% are from the industrial market - exclusively.

FogLAMP started with an Apache 2 license and an open Git repository. However, it did not start with a formal governing body tracking contributors and contributions. Early architecture was a joint effort between OSIsoft, Dinaomic, process manufacturers and other software suppliers. Efforts by many were combined in terms of ideas, architectures, writing code, testing, documentation, bug fixing and contracting. Here’s a partial list of the companies involved.

Beckhoff - PLC Vendor | Nexcom - Industrial Gateways |

Dianomic - IIoT Software | Nokia - Wireless Communications |

Flir - IR/Gas Cameras | OSIsoft - Data Infrastructure |

General Atomics - Predator Drone | Rovisys - Industrial SI |

Google - Search-ML-Cloud-TPUs | Transpara - HMI for Process Manufacturers |

JEA - Energy/Water Company | Wago - PLC Vendor |

Motorsports.ai - Racing Digital Twins | Zededa - VMs for IoT |

Demonstrate evidence of, or a plan for, interoperability, compatibility or extension to other LF Edge Projects. Examples may include demonstrating modularity (ability to swap in components between projects).

Fledge and Eve were the first two projects to engage in joint interoperability and compatibility engineering and testing. The effort started with FogLAMP in late 2018 before the formation of LF Edge. It was due to the efforts of Zededa and the Linux Foundation that encouraged Dianomic and OSIsoft to become founding board members. During that process, in December of 2019, a request was made to contribute FogLAMP to LF Edge.

When the board asked for its first joint project demo, EVE and Fledge stepped up and produced a model wind turbine.

And an industrial Flir Infrared camera demonstration. Fledge looks forward to more extensions with Akraino, Open Horizon and Intel SDO integrations in 2020.

Fledge has a unique architecture that enables rapid south and northbound protocols and data mappings to be written (w/o a new micro service). The code can be potentially be written in any language. Currently available languages include C/C++, Go and Java (via dynamic linking) and Python (via shim layers). This list can be extended to other relevant languages as needed. Using Python a relatively junior engineer can be very productive (minutes to hours for data mappings, days new protocols). Most industrials have modest development expertise. This feature is a major source of our community activity and addresses a critical pain point in the industrial market.

A recent request was made to leverage southbound connectivity across LF Edge Projects. Fledge is in several PoCs where Fledge has been used to enable commercial platforms south connections. AWS Greengrass being one of them. We could imagine doing a similar northbound integration with the EdgeX Project if desired.

The Fledge roadmap also includes the integration and testing with systems and subsystems lower in the stack. This is an immediate opportunity for cross project cooperation.

- Life-cycle-management of HW and OS - EVE

- Fledge + EVE (FLIR camera demo) - Industrial Use Case

- Presented Working demo February 18 (reference meeting recording: 36:30 - 56:30)

- Fledge + EVE (FLIR camera demo) - Industrial Use Case

- Protocols/projects that enable IIoT "south of diodes" to be managed - Open Horizon

- Easy provisioning and life-cycle-management of emerging network edge technologies and services - Akraino

- Blueprint Proposal: https://wiki.akraino.org/pages/viewpage.action?pageId=20316568

- HW based key management to create “trusted” processes, devices, networks, communications and data services - Intel SDO

- Protocol bridge Fledge <> EdgeX – Discussed at joint Fledge TSC / EdgeX TSC call.